As usual, many thanks to all those who have bought me a coffee. If you have not contributed and like what you see why not pop over to Buymeacoffee.com and contribute to the funding of the web site hosting services.

When I looked over my boats for a post race check I noticed a few small things that could make a difference to performance

Corrosion in the gooseneck bearings

If you are a regular sailor of DF's on salt water I am sure you will have seen the impact of salt on the gooseneck bearing. Despite washing and copious amounts of corrosion X I have suffered from rust in the bearings although to be fair I may have missed a wash or two. The brown ring below the stainless band in the picture below is the upper bearing for the gooseneck. It should look shiny and new but is now brown and manky. Who know what the bearing looks like inside. The solution is to either buy more bearings from your DF stockist or get a batch from a bearing supplier (UK based but will ship).In this case look for part SMR106ZZ or SMR106ZZ EZO. I am told these will not rust but have yet to test them. They are on the way and will be fitted before next TT.

Shrinking sail ties

I noticed looking at my rigs was that one or two of the sail ties had tightened up so they will be replaced. Always worth checking the rigs ideally before racing.

Large tell tales

I also saw that the biggest tell tales were the easiest to see. Ken Binks had the biggest. Lesson learned

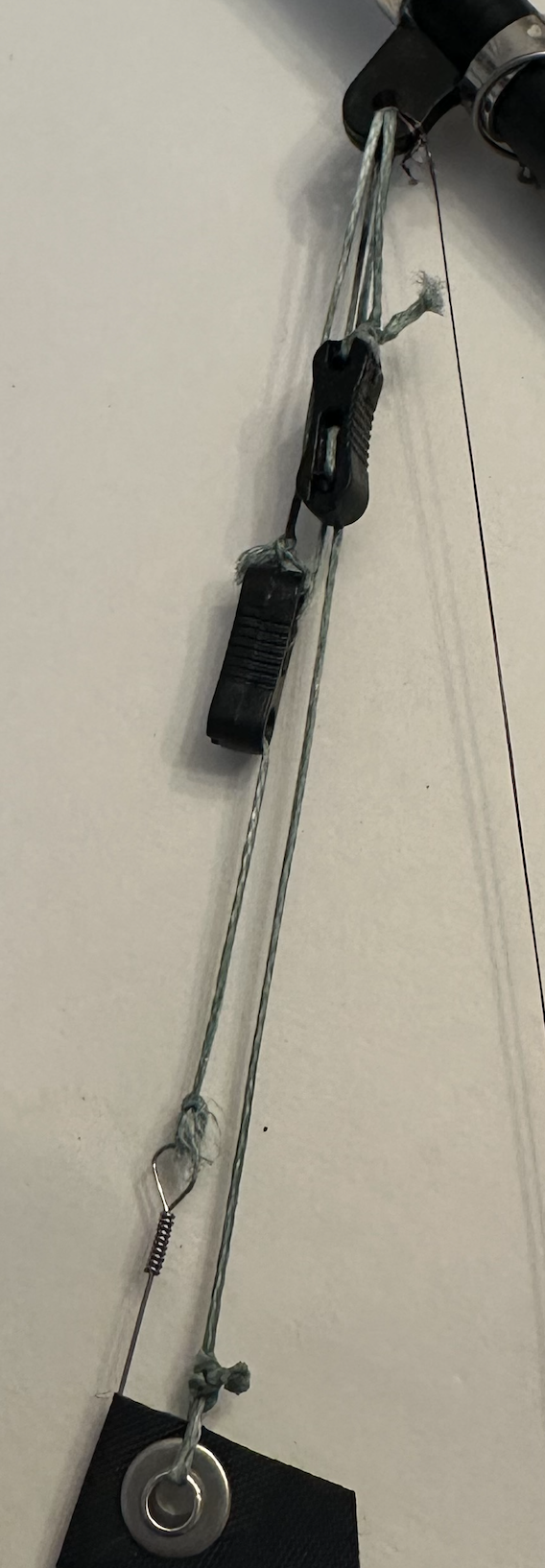

Rigging the bowsies correctly

The other other thing I realise is that the rigging guide tempts you to set up the bowsies so they pull the wrong way. I was notaware you were allowed to re rig them so the bowsie pull against the load rather than towards it.

This is what I currently have on my DF

And this is my IOM

A siezed rusted rudder servo

Lastly my digital rudder servo (gold coloured, seized completely and I was going to throw it away but a call to Richard Callas saved the day. He suggested taking the cover off and oiling the cog that sticks out the top of the motor case and then after the oil has sunk in easing the cog with a pair of pliers whick loosened the the motor and I was able to get it working again. However with the casing off, the motor just spins round and round so I though it was broken. However when I put the case back on the servo, it operated correctly. I put the servo back in the boat and it performed perfectly on the day. After each days racing I remove the servo arm apply a tiny bit of corrosion X to the top of the rudder servo so I dont get a repeat of the corrosion.

I hope these ideas help you and will add these to the DF 65 section of the web site

コメント